Quality Aggregates Where You Need Them

Zero Lift can provide a wide range of aggregates from decorative aggregates for domestic use to high-PSV aggregates for highway work. limestone, sand and gravel, for commercial or construction use or any other application that you require. Everything is delivered in our revolutionary non Tipping Zero Lift vehicle meaning a safer, quicker and more controlled delivery.

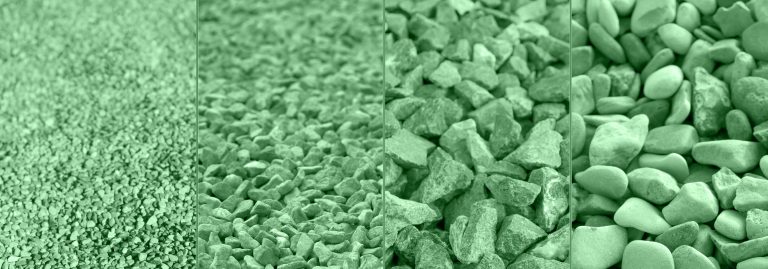

Types Of Aggregates

Aggregates can be used for a variety of construction uses, including ready-mixed concrete production, pre-cast concrete, brick and block manufacture and asphalt production. Specialist sands can also be used for glass making, horticulture, agriculture and leisure.

Aggregates used in concrete consist of geological materials such as gravel, sand and crushed rock. Specific aggregates, or combinations of aggregates, are selected for their durability, strength and ability to achieve specific project outcomes.

The size of aggregates will be the main factor when determining the strength of concrete, so the right size of coarse aggregates to use will depend on the demands of your project.

Aggregates are classified as either coarse or fine, both are further categorised into classifications based on size. Coarse aggregates are granular particles greater than 4mm with a usual range of 6mm to 31.5mm. Fine aggregates, however, usually consist of sand or crushed stone and are less than 4mm in diameter. The most commonly used size in construction is 20mm and the largest sizes are most commonly used in mass concrete or for roads and sub base.

There are 4 main types of aggregate used in landscaping and construction, these consist of gravel, sand, crushed rock and concrete fill. These vary in material type and size, with each type of aggregate serving a unique purpose within specific applications.

- Highest Quality Aggregates

- Guaranteed Delivery Slots

- Safe Non Tip Delivery

- Professional Service

Popular Types of Aggregate

0-10mm Ballast

As an essential ingredient in any concrete mix, 10mm ballast is a popular choice for commercial and domestic construction projects, containing an ideal mix of course sand and gravel.

0-20mm Ballast

If you are mixing concrete, a vital ingredient is the right grade of ballast, which is why the 20mm mix of coarse sand and gravel is ideal for a wide range of construction projects in a domestic or commercial environment.

Screened and Recycled Ballast

Screened ballast is a multipurpose material that’s typically utilized for footpaths, driveways, backfill, and blinding hardcore. It is made up of crushed stone and is screened to eliminate finer particles. Recycled ballast is an eco-friendly option that is produced as a by-product of the construction industry. Recycled screened ballast has fine particles removed during the screening process and is washed to produce a high-quality product.

Gravel

Gravel is available in a vast range of colours, sizes and materials, suitable for almost any application in domestic or commercial projects. We are able to provide shingle, 4mm-10mm and 4mm-20-mm shingle. All of which can be used for improved drainage or decorative purposes, it is often used for driveways or paths, covering a border or flowerbed, which will keep weeds at bay.

Recycled Concrete

Recycled concrete is a sustainable material that can be used in a variety of ways. It is made by crushing concrete and other recycled aggregates. There are several types of recycled concrete available, including Type 1 recycled crushed concrete, type 2 recycled 6F2/CF2, Type 3 tarmac road plainings (unscreened), type 4 tarmac road plainings (screened), oversized clean crushed concrete & gabion fill granite. As well as being an eco-conscious material that prevents demolition waste from being sent to landfill, sit is a relatively coarse aggregate, low maintenance and provides drainage to sub-base projects like roads, paths, car parks and driveways.

Using recycled concrete is a cost-effective and environmentally-friendly alternative to quarrying new natural resources. It helps reduce the amount of demolition waste that ends up in landfills. Additionally, using recycled concrete in your building project may help you obtain certain eco-credentials.

Sand

Sand is one of the most abundant and versatile raw materials on earth, with a huge range of uses from mixing concrete and perfecting paving, to filtering water and creating golf bunkers. Each type of sand has different uses and benefits, for example, building sand can be mixed with cement and water to make mortar for bricklaying and because it is a softer sand, it can also be used for rendering and pointing, but is not suitable for cement mixes. Instead, you’ll need sharp sand, which is a general-purpose and coarse sand suitable for use in concrete construction, laying slabs and block paving.

Reject sand is a by-product of making building sand, it is also known as fill sand and is typically used for backfilling service trenches, as it is clay based and contains minimal amounts of stone.

Topsoil

Topsoil is suitable for a variety of uses, including improving soil quality for the next growing season, creating ideal conditions for new turf to grow, as a cost-effective bulk fill where high volumes of soil are needed and can be used for filling a raised bed, germinating grass seed and has free draining benefits, as well as containing nutrients that plants need to grow.

Type 1 MOT

Made from crushed limestone, concrete and granite, type 1 MOT aggregates are generally used a base bulk-fill or levelling material for driveways, roads and garden projects. Type 1 aggregates compact well and are a versatile option for building sturdy sub-base foundations.

Type 1 granite is often laid under tarmac and compacted as a base for highways, due to the durability of the material which is also approved by the Ministry of Transport. This produce is made up of a range of particle sizes, ensuring it compacts well to form a surface that performs well under high traffic and heavy loads.

Type 1 concrete is most commonly used as a sub-base filling material and is one of the most widely used aggregates in the commercial construction industry. It is mostly made up of pieces of concrete, which have been crushed into around 50mm size and can be used for any project requiring type 1 materials.